Introduction

If you’re navigating the world of K25LP Throttle Control machines, you know that throttle control is a game changer. It’s not just about speed; it’s about precision and performance. Whether you’re operating in tight spaces or need to maneuver around obstacles, having a responsive throttle can make all the difference.

But what happens when your throttle control isn’t quite up to par? Frustration sets in as you struggle with sudden surges or sluggish responses. Fear not! You’re not alone, and there are plenty of ways to enhance your K25LP throttle experience. Let’s dive into some essential insights and tips that will help transform your operation for the better.

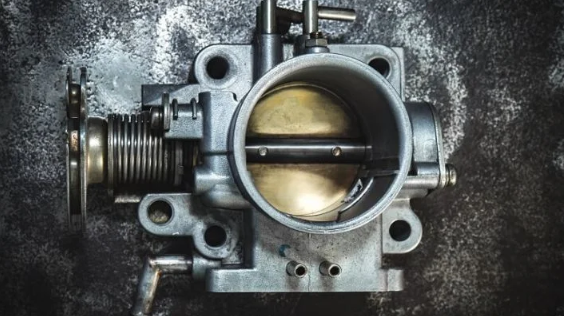

Understanding the Basics of Throttle Control

Throttle control is the heart of machine operation. It manages engine power and speed, impacting how quickly your K25LP responds to commands.

At its core, throttle control governs the flow of fuel and air into the engine. A precise balance ensures smooth acceleration or deceleration. When you press down on the pedal, you dictate how much energy reaches the wheels.

Understanding this dynamic can help operators make more informed decisions while handling their machines. Throttle response varies with terrain; climbing a hill requires different input compared to navigating flat ground.

In essence, mastering throttle control means mastering your machine’s capabilities. The right adjustments lead to improved efficiency and performance in various tasks. Knowing when to ease off or push forward becomes second nature over time.

Common Issues with K25LP Throttles

The K25LP throttle system is generally reliable, but it can face some common issues that affect performance. Users often report erratic throttle response. This inconsistency can lead to sudden accelerations or decelerations, making operation challenging.

Another frequent problem involves sticky throttles. Dirt or debris may build up around the throttle mechanism, causing it to stick in place. This not only hampers control but also poses safety risks.

Additionally, calibration errors might occur over time due to wear and tear on components. When this happens, the machine may not respond as expected during critical tasks.

Electronic glitches can impact the digital display linked with throttle operations. These malfunctions could misrepresent speed settings or fuel efficiency data, complicating user experience further.

Tips for Improving Throttle Control on K25LP Machines

Improving throttle control on K25LP machines can significantly enhance performance and efficiency. Start by familiarizing yourself with the machine’s controls. Understanding how each function operates allows for more precise handling.

Practice makes perfect. Spend time operating your machine in a safe environment, focusing solely on throttle responsiveness. Gradually increase speed as you gain confidence.

Consider adjusting your grip and body posture while driving. A relaxed but firm grip can lead to smoother acceleration and deceleration, reducing abrupt movements.

Utilize slow-speed settings when navigating tight spaces or delicate tasks. This level of control minimizes the risk of overshooting or causing damage.

Don’t underestimate the power of communication with your team if you’re working alongside others. Clear signals can help coordinate actions more effectively, ensuring everyone is on the same page regarding speed adjustments.

Utilizing the Digital Display to Enhance Throttle Control

The digital display on your K25LP is more than just a sleek interface; it’s a powerful tool for optimizing throttle control. By monitoring real-time data, you can make informed adjustments to enhance performance.

Pay attention to the RPM readings. This information helps you fine-tune your speed and power delivery, ensuring smoother operation in various conditions. A sudden spike or drop could indicate that adjustments are necessary.

Utilizing the fuel consumption metrics displayed can also guide your throttle use. Efficient throttle control not only improves performance but conserves fuel as well.

Don’t overlook diagnostic features either. If you’re experiencing issues, these indicators help identify problems before they escalate, keeping your machine running smoothly and efficiently.

Regularly checking this digital display empowers operators to maintain better control over their K25LP’s functionality while maximizing its capabilities on every job site.

The Importance of Regular Maintenance

Regular maintenance is essential for optimal performance of your K25LP throttle control. It ensures that all components function smoothly and efficiently, prolonging the life of your equipment.

Neglecting maintenance can lead to more significant issues down the line. Minor adjustments or replacements are easier and cheaper than full-blown repairs caused by wear and tear.

Scheduled checks allow you to identify potential problems before they escalate. This proactive approach minimizes downtime, keeping operations running seamlessly.

Another benefit is improved safety. Properly maintained throttle systems reduce the risk of malfunctions, ensuring a safer working environment for everyone involved.

Incorporating routine maintenance into your schedule not only enhances performance but also boosts productivity. With reliable machinery at hand, you can focus on getting the job done without unexpected interruptions or mishaps.

Upgrading to a Newer K25LP Model for Improved Throttle Control

Upgrading to a newer K25LP model can dramatically enhance your throttle control experience. Modern models come equipped with advanced technology that provides smoother acceleration and deceleration.

These enhancements often include improved sensors that offer real-time feedback, allowing for more precise adjustments. Operators will find it easier to maintain optimal speed in various conditions.

Additionally, the latest designs focus on ergonomic features, making them user-friendly. A better interface means you can react quickly without compromising safety or efficiency.

Investing in an upgraded model not only contributes to performance but also boosts overall productivity. The benefits extend beyond just throttle control; they encompass reliability and ease of use as well.

Choosing a newer version could be a game-changer for both seasoned operators and newcomers alike. Experience firsthand how technological advancements make all the difference in handling machinery effectively.

Conclusion

Improving your K25LP throttle control can significantly enhance your machine’s performance. Start by understanding the basics of how to throttle control functions and being aware of common issues that might be hindering efficiency. Applying practical tips for improvement, coupled with the utilization of digital displays, can lead to better responsiveness.

Regular maintenance is crucial in ensuring that your K25LP operates smoothly. It helps you catch potential problems before they escalate. If you’re still struggling after applying these strategies, consider looking into upgrading to a newer model designed with advanced features tailored for optimal throttle control.

Investing time and effort into these areas will ultimately yield noticeable benefits in both operation and user experience with the K25LP. With proper attention and care, you’ll find that mastering your throttle control not only enhances productivity but also prolongs the lifespan of your equipment.